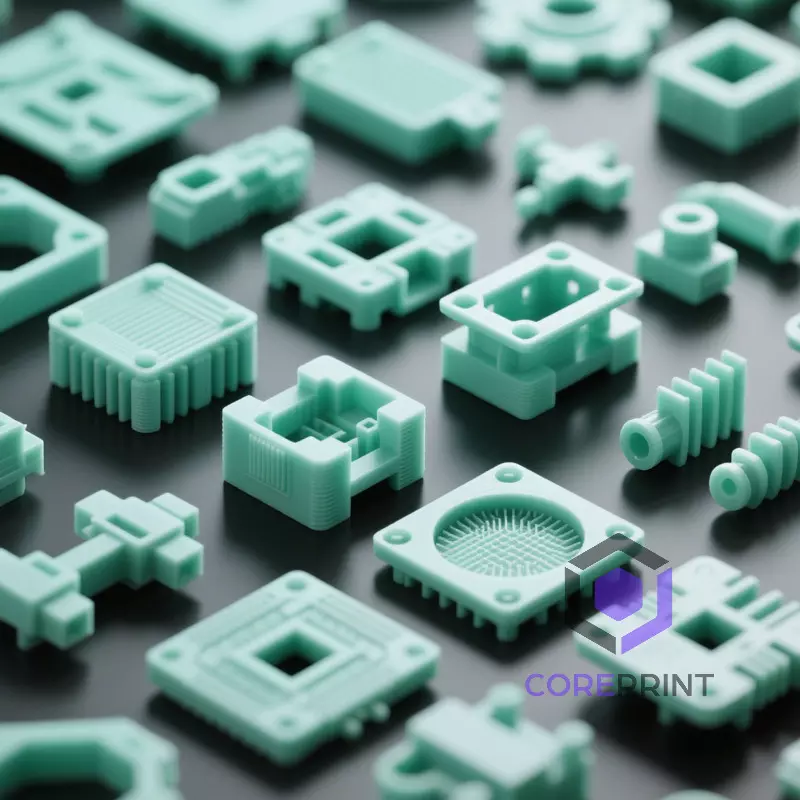

High-toughness Resin 3D Printing Service

High-toughness resin excels in impact resistance and bendability, with elongation at break of 50%-150% and impact strength over 20kJ/m², combining rubber-like elasticity and plastic rigidity (Shore A 40-90). Printed parts withstand repeated bending, extrusion, or drop tests while maintaining detail precision at 0.05-0.1mm layer thickness, supporting post-processing like drilling and assembly. Ideal for functional prototypes requiring dynamic performance, such as snap-fit connectors, flexible gears, and shock-absorbing structures, accelerating validation for complex stress scenarios.

Common 3D printable products:

- Industrial Equipment & Mechanical Parts

- Automotive & Transportation Such as car bumper prototypes

- Consumer Electronics & Wearables Used for flexible headphone ear hooks

What do you want printed?

You can also send us 3D object files at our Email:jerry@coreprint3d.com

High-toughness Resin Material Properties

4-Resin_Transparent Resin

| Tensile Strength / Modulus (Mpa) | Yield Strength / Modulus (Mpa) | Elongation (%) | Heat Deflection Temperature (°C) |

| 41/187 | 75/1740 | 9 | 52 |

How Does Resin 3D Printing Work?

The SLA (Stereolithography) process for resin materials is as follows:

First, design a 3D model with CAD software and import it into slicing software to layer it (0.05-0.1mm thickness) and generate support structures. During printing, the lifting platform submerges into a liquid photosensitive resin tank, where an ultraviolet laser or projector cures the resin layer by layer according to sliced data, forming each contour as the platform lowers by one layer thickness. After completion, the workpiece is removed, supports are detached, and uncured resin is cleaned with alcohol. Finally, post-curing in a UV chamber enhances the resin’s strength, gloss, and weather resistance. With high precision (up to ±0.1mm), this technology is ideal for detailed complex parts like precision molds, jewelry prototypes, and medical guides.

Get An Accurate Quote Quickly

If you have 3D printing needs, you can leave your email address, and we will reply to you within 30 minutes.

Email:

jerry@coreprint3d.com

Phone:

+86:180 2696 3929

Jieshun Technology Center, Longhua District, Shenzhen

Dongguan Songshan Lake International Innovation and Entrepreneurship Community