Metal 3D Printing: A Revolutionary Solution for Modern Manufacturing

In modern manufacturing, producing low-volume metal components has long been constrained by efficiency and cost challenges. Traditional methods like casting and forging excel in mass production but struggle with small batches (ranging from dozens to hundreds of units) due to lengthy processes, high tooling costs, and limited design flexibility. Metal 3D printing technology offers a transformative solution to these issues.

1. Eliminating Tooling Costs for Substantial Savings

Traditional low-volume production often allocates 30-50% of total costs to (tooling design, fabrication, and debugging), which can take weeks or months. Metal 3D printing uses an “additive manufacturing” approach, directly converting digital models into physical parts without molds:

- 80%+ cost reduction in tooling for 50-500-unit orders

- Avoids cost-prohibitive tooling (cost spreading) for small batches

- Ideal for customized prototypes or low-volume production

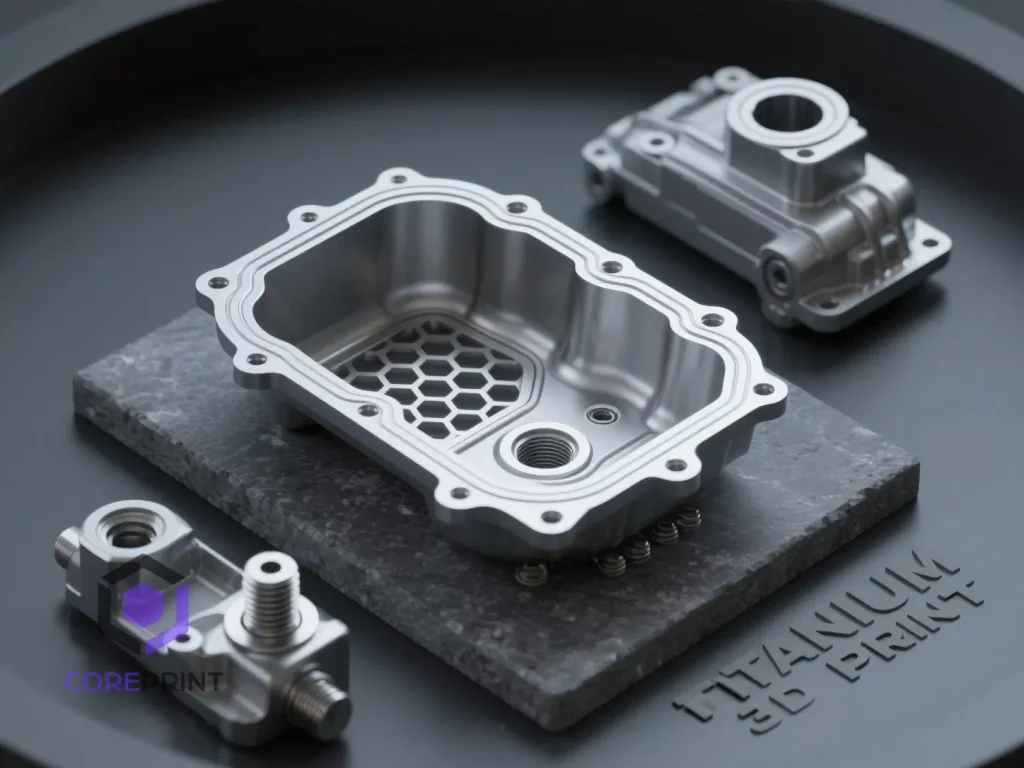

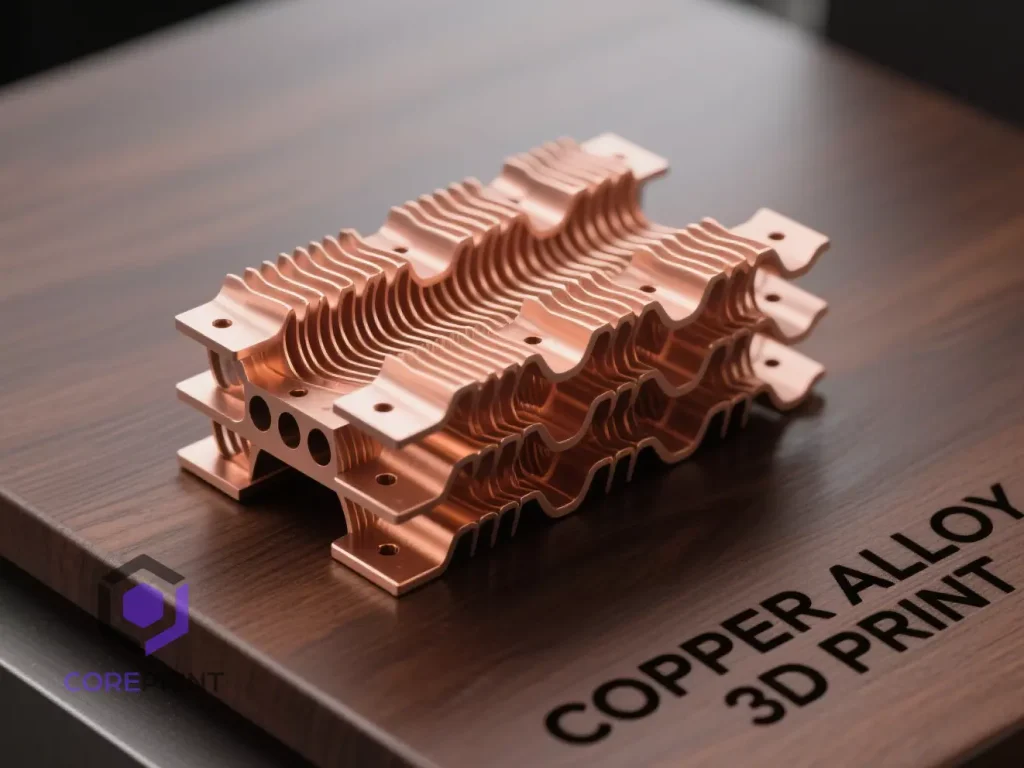

2. Unmatched Design Freedom Beyond Traditional Limits

Metal 3D printing transcends the “subtractive manufacturing” constraints of conventional methods, enabling complex structures:

- Intricate geometries: Internal channels, lattice structures, and hollow designs achievable in one piece

- Topology optimization: Lightweight yet strong components (critical for aerospace)

- Customization: Rapid parameter adjustments for multi-specification production

For example, an automotive manufacturer consolidated 5 assembled engine parts into 1 via metal 3D printing, boosting assembly efficiency by 80%.

3. Accelerated Production Cycles for Faster Market Entry

Speed is critical in low-volume production. Metal 3D printing excels here:

- 24-hour turnaround from digital model to finished part (vs. 2-4 weeks traditionally)

- Instant design iterations without retooling

- Ideal for urgent spare parts or time-sensitive applications

A medical device company reduced a orthopedic implant’s prototyping cycle from 45 to 7 days, gaining a market edge.

4. Enhanced Material Efficiency for Sustainable Manufacturing

Traditional machining wastes 50-70% of raw materials through “subtractive” processes. Metal 3D printing’s “additive” approach achieves:

- 90%+ material utilization with minimal waste

- Significant savings for expensive alloys (e.g., titanium, superalloys)

- Aligns with green manufacturing trends by reducing scrap

5. Flexibility and Scalability for Dynamic Production

Metal 3D printing‘s “digital manufacturing” model enables unprecedented adaptability:

- Multi-variant production: Seamless switching between designs via file updates

- No MOQ restrictions: Identical processes for 1 or 100 units

- Hybrid production: Combines with CNC machining for precision-finished parts

Conclusion: The Future of Low-Volume Manufacturing

Metal 3D printing is redefining low-volume production standards with its tooling-free, rapid, and flexible advantages. Its applications span aerospace, medical devices, automotive, and high-end equipment manufacturing, offering immense potential. As technology advances and costs decline, metal 3D printing will bridge design innovation and efficient production, becoming an indispensable pillar of modern manufacturing.