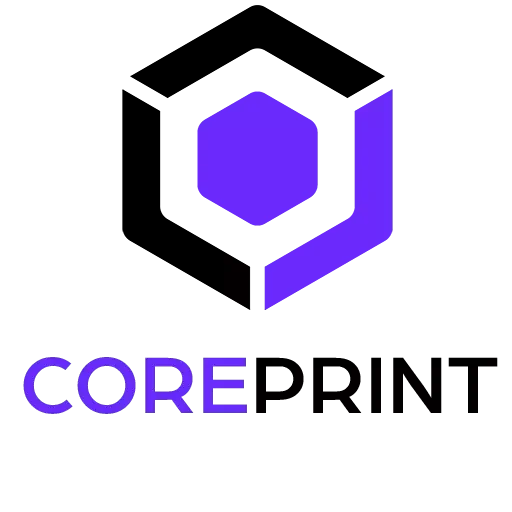

Aluminum 3D printing material

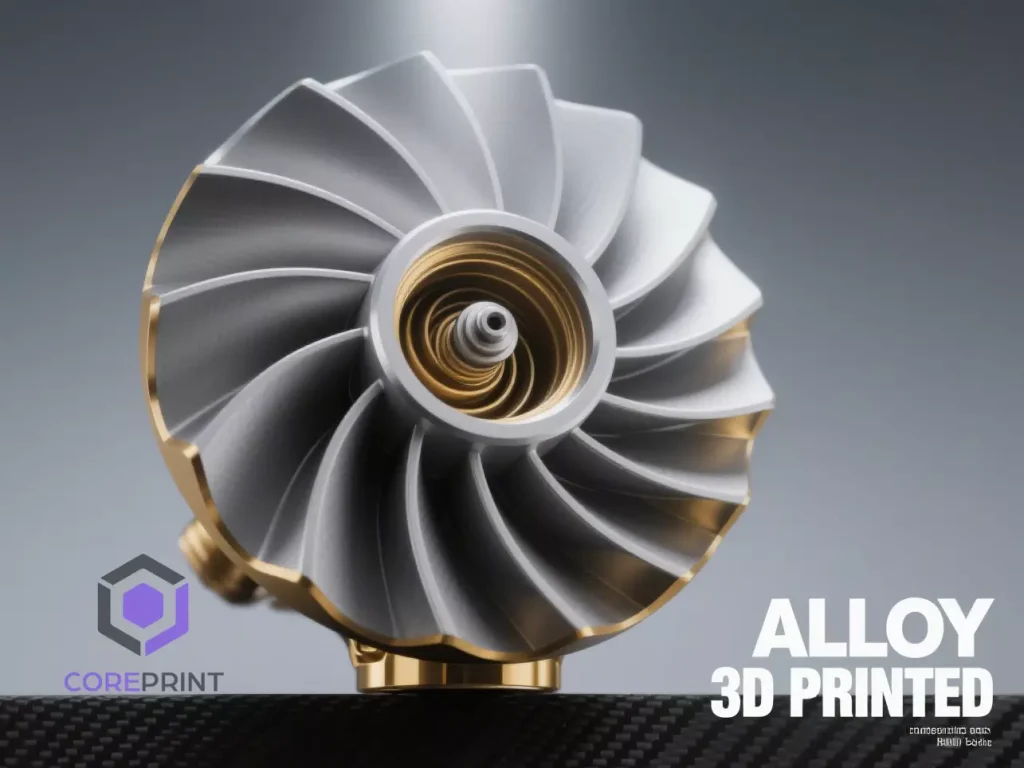

Aluminum alloy 3D printing has remarkable advantages, featuring high design freedom (capable of manufacturing complex structures and achieving customized production), excellent material properties (both high strength and light weight, as well as good mechanical properties), high production efficiency (rapid prototyping and integrated manufacturing are possible), and high material utilization rate (precisely adding materials), etc.

Primary Benefits:

- High stiffness and strength relative to weight

- Thermal and electrical conductivity

- High temperature and corrosion resistance

What do you want printed?

You can also send us 3D object files at our Email:jerry@coreprint3d.com

Aluminum (AlSi10Mg) Material Properties

| Resolution | Condition | Ultimate Tensile Strength | Yield Stress | Elongation | Hardness | |

| Aluminum (AlSi10Mg) | High (20 μm) | Stress Relieved | 268 Mpa | 180 Mpa | 15% | 46 HRB |

| Normal (30 μm) | Stress Relieved | 345 Mpa | 228 Mpa | 8% | 59 HRB | |

| Large Format (40 μm) | Stress Relieved | 296 MPa | 186 MPa | 10% | 50 HRB |

3D-Printed Aluminum Part Dimensions

Maximum part size and minimum feature size will vary based on selected resolution. 3D-printed aluminum is available in high, normal, and large format resolutions.

| Resolution | US | Metric | |

| Maximum Dimensions | High (20 um) | 3.8 in.x 3.8 in.x 3.7 in. | 98mm x98mm x94mm |

| Normal (30 um) | 9.6 in.x 9.6 in.x 13.0 in. | 244mmx244mmx330mm | |

| Large Format (40 um) | 31.5 in. x 15.7 in.x 19.7 in. | 800mmx398mm x500mm | |

| Minimum Feature Size | High (20 um) | 0.015 in. | 0.381mm |

| Normal (30 um) | 0.030 in. | 0.762mm | |

| Large Format (40 um) | 0.015 in. | 0.381mm |

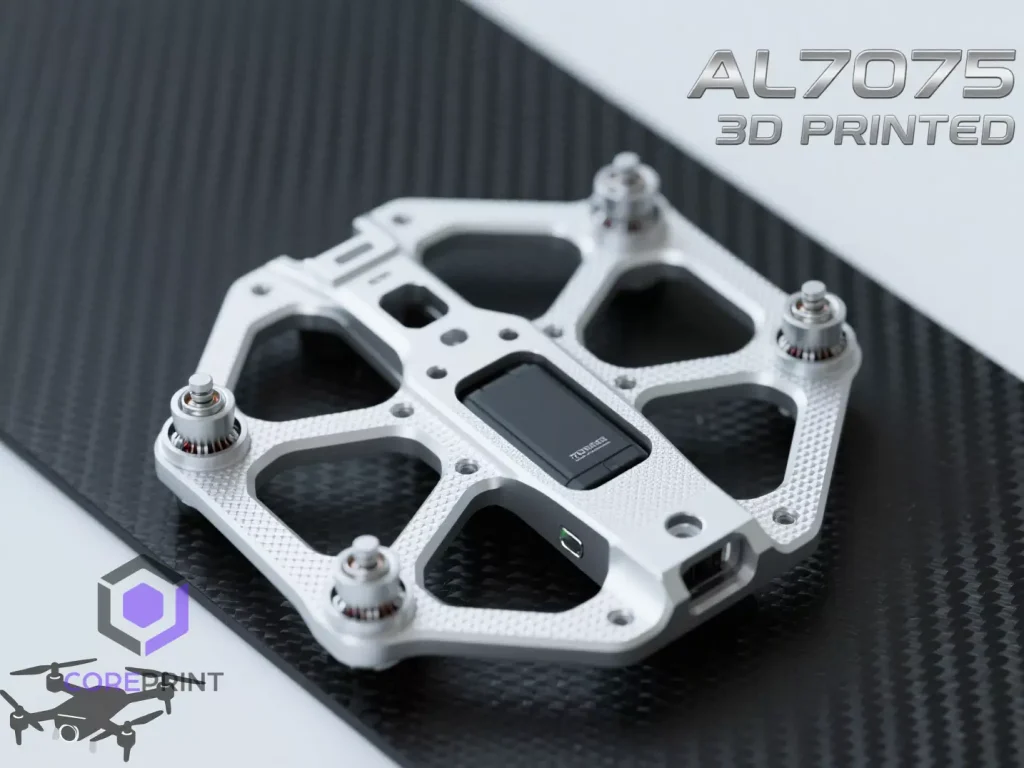

How Does Metal 3D Printing Work?

The DMLS machine begins sintering each layer—first the support structures to the base plate, then the part itself—with a laser aimed onto a bed of metallic powder. After a cross-section layer of powder is micro-welded, the build platform shifts down and a recoater blade moves across the platform to deposit the next layer of powder into an inert build chamber. The process is repeated layer by layer until the build is complete.

When the build finishes, an initial brushing is manually administered to parts to remove a majority of loose powder, followed by the appropriate heat-treat cycle while still fixtured in the support systems to relieve any stresses. Parts are removed from the platform and support structures are removed from the parts, then finished with any needed bead blasting and deburring. Final DMLS parts are near 100 percent dense.

Get An Accurate Quote Quickly

If you have 3D printing needs, you can leave your email address, and we will reply to you within 30 minutes.

Email:

jerry@coreprint3d.com

Phone:

+86:180 2696 3929

Jieshun Technology Center, Longhua District, Shenzhen

Dongguan Songshan Lake International Innovation and Entrepreneurship Community