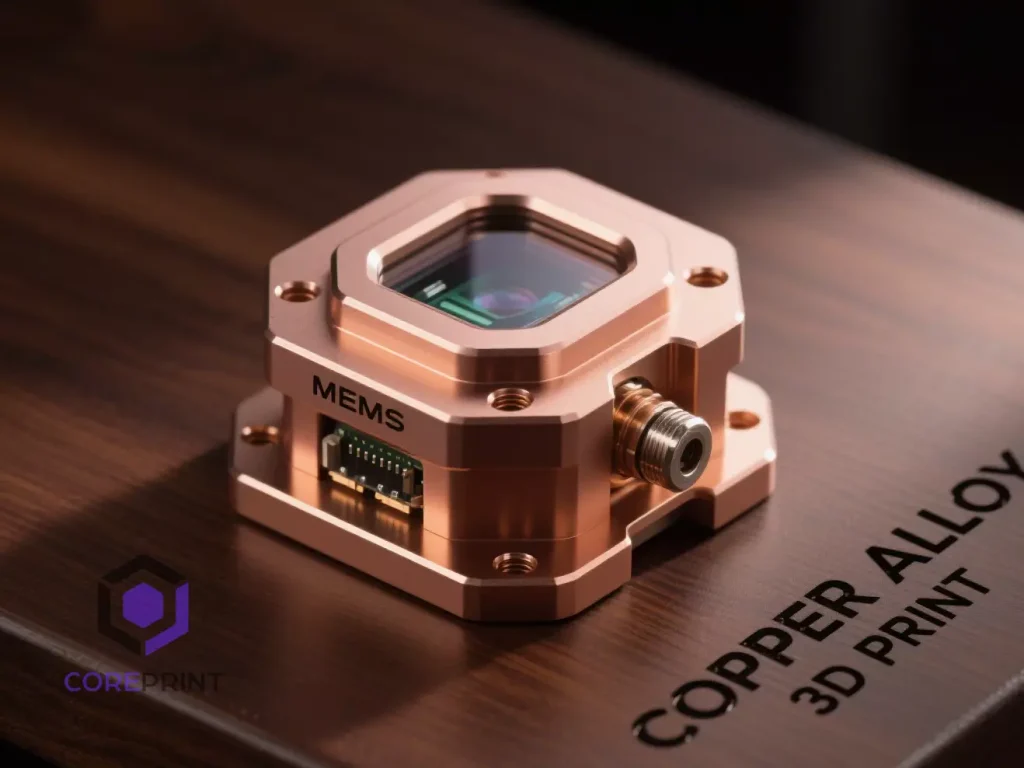

Copper 3D Printing Service

Key Advantages:

- High electrical conductivity for electronics applications

- Exceptional thermal conductivity for heat transfer uses

- Good corrosion resistance in specific environments

- Decent formability for detailed designs

What do you want printed?

You can also send us 3D object files at our Email:jerry@coreprint3d.com

Copper Material Properties

| Ultimate Tensile Strength | Yield Strength | Hardness (Rockwell) | Electrical Conductivity | Thermal Conductivity | |

| Copper C101 | 41 ksi | 8.7-34.8 ksi | 40 | 96.5% (IACS) | 390 - 398 W/(m⋅°C) |

| (283 MPa) | (60-240 MPa) | ||||

| Copper C110 | 32-41 ksi | 8.7-34.8 ksi | 95 | 101.5% (IACS) | 380 - 388 W/(m⋅°C) |

| (220-280 MPa) | (60-240 MPa) | ||||

Copper Part Dimensions

Maximum part size and minimum feature size will vary based on selected resolution. 3D-printed Copper is available in high, normal, and large format resolutions.

| Factory Capabilities | Network Capabilities | |

| Maximum Part Size | 559mm x 356mm x 95.3mm | 650mm x 650mm x 300mm |

| Minimum Part Size | 6.35mm x 6.35mm | 0.50mm |

| Tolerances | ±0.13mm | ±0.020mm |

| Minimum Wall Thickness | 1.02mm | 0.75mm |

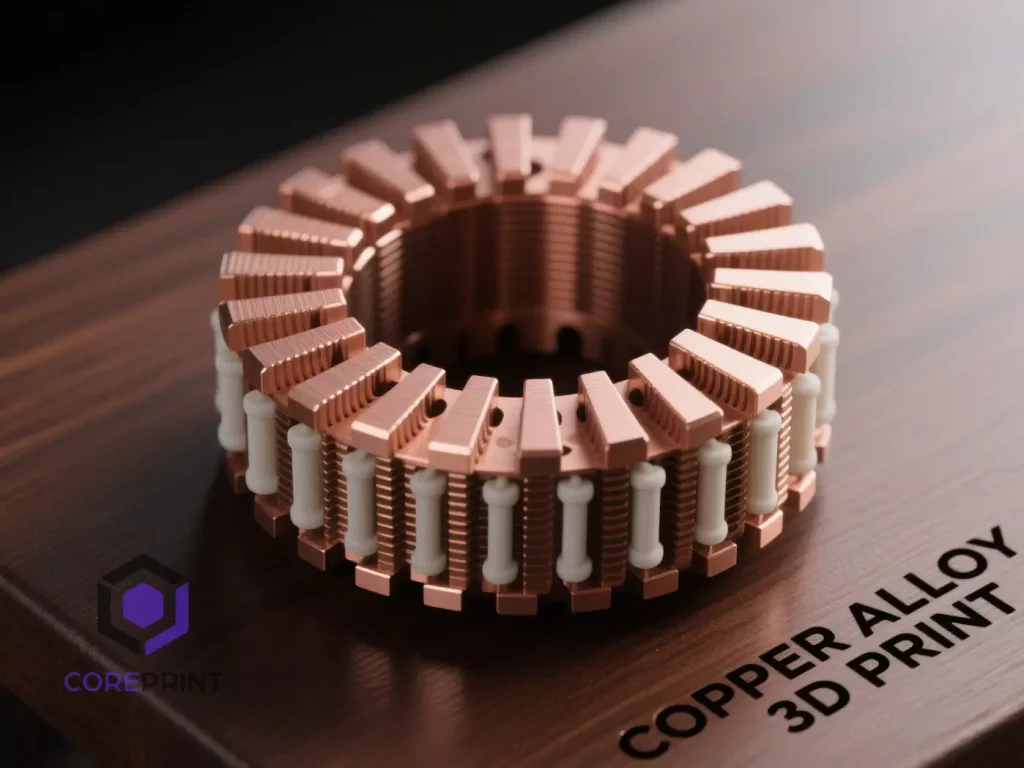

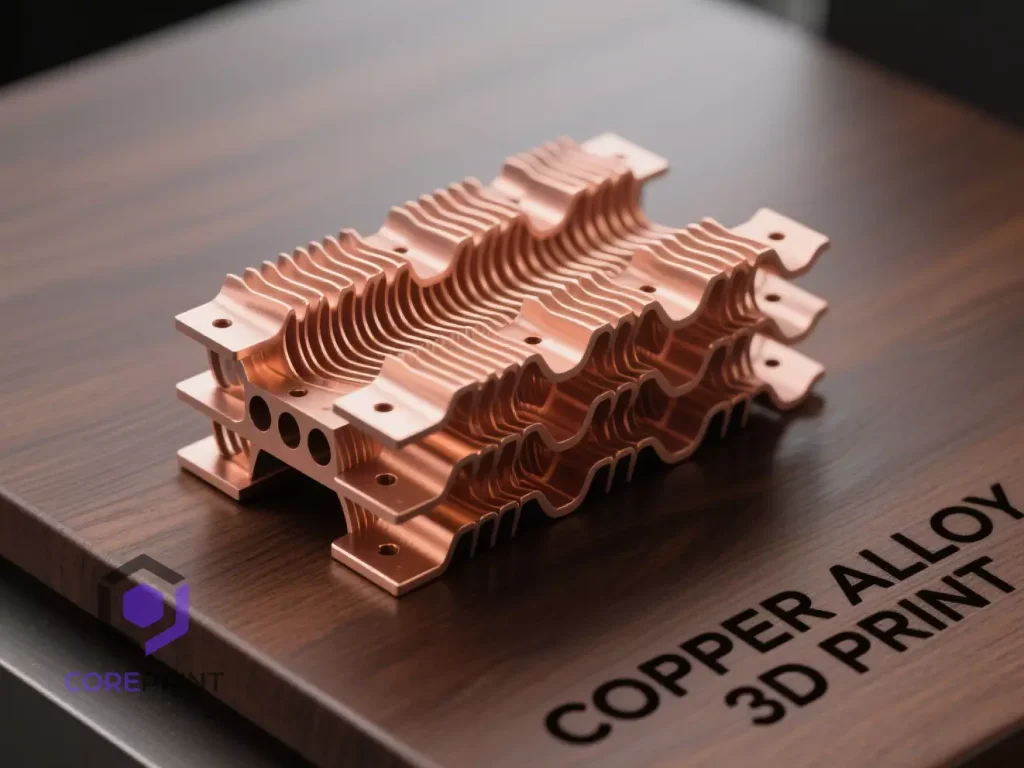

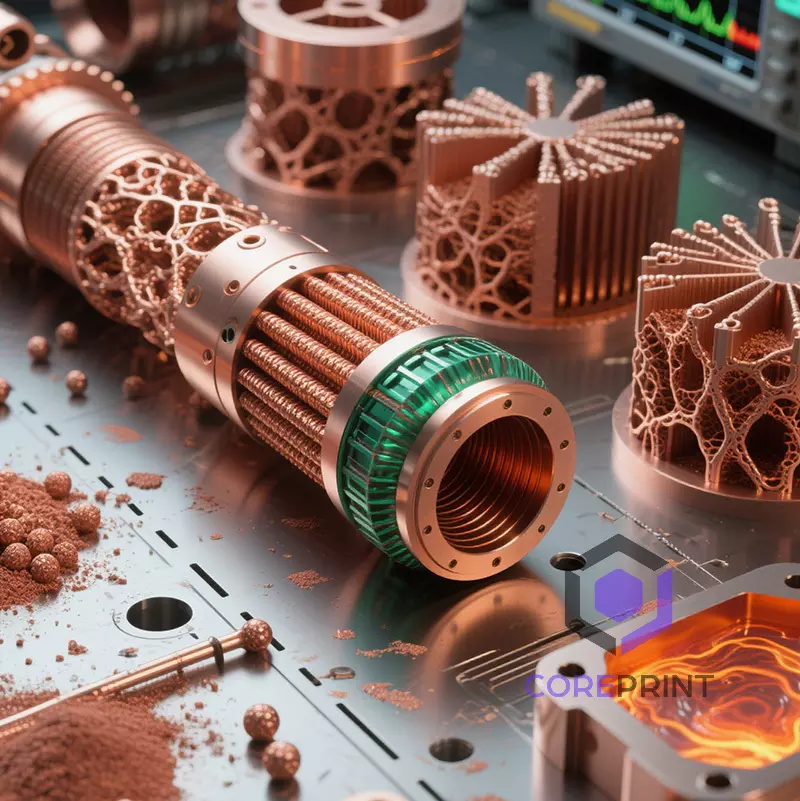

Copper 3D Printing Material Options

Copper 3D printing has diverse applications. In electronics, its high electrical conductivity makes it perfect for components like circuit boards, ensuring efficient signal transmission. In heat exchangers for the automotive and energy sectors, copper’s excellent thermal conductivity enhances heat dissipation. Its malleability allows for customized designs.

The characteristics of Copper alloy materials are as follows:

- tensile strength (Mpa) typically around 200 – 400

- yield strength (Mpa) ≥ 70

- elongation rate (%) ≥ 40. In heat – treated state

- properties can be further optimized, meeting specific industrial demands.

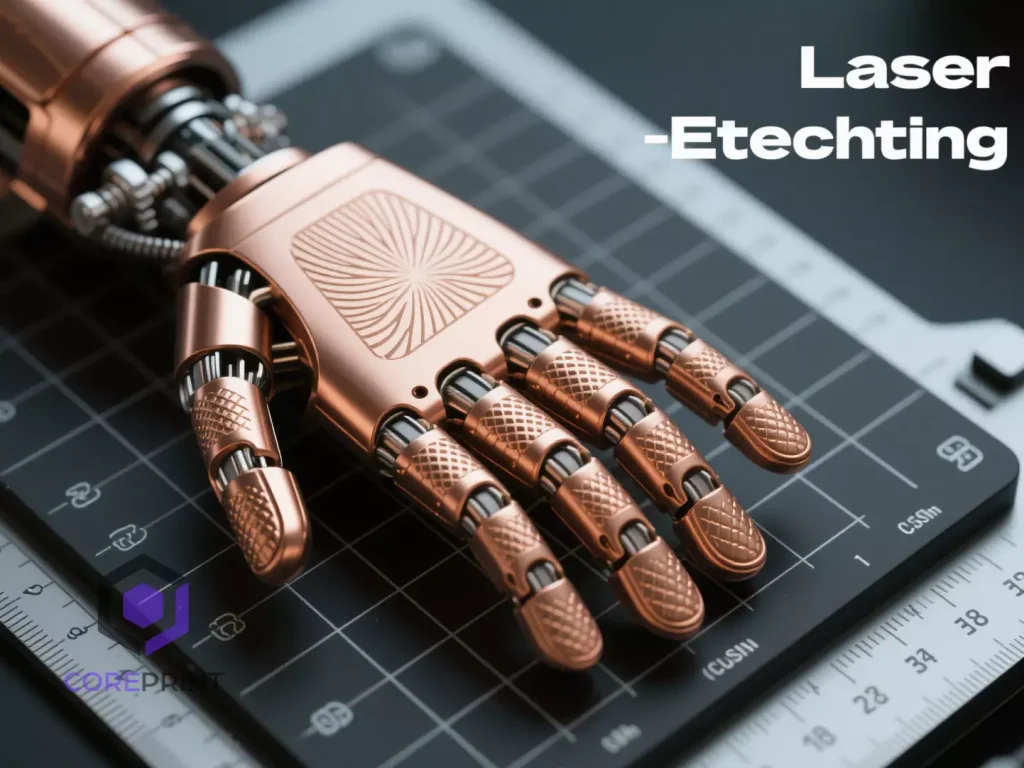

How Does Metal 3D Printing Work?

The DMLS machine begins sintering each layer—first the support structures to the base plate, then the part itself—with a laser aimed onto a bed of metallic powder. After a cross-section layer of powder is micro-welded, the build platform shifts down and a recoater blade moves across the platform to deposit the next layer of powder into an inert build chamber. The process is repeated layer by layer until the build is complete.

When the build finishes, an initial brushing is manually administered to parts to remove a majority of loose powder, followed by the appropriate heat-treat cycle while still fixtured in the support systems to relieve any stresses. Parts are removed from the platform and support structures are removed from the parts, then finished with any needed bead blasting and deburring. Final DMLS parts are near 100 percent dense.

Get An Accurate Quote Quickly

If you have 3D printing needs, you can leave your email address, and we will reply to you within 30 minutes.

Email:

jerry@coreprint3d.com

Phone:

+86:180 2696 3929

Jieshun Technology Center, Longhua District, Shenzhen

Dongguan Songshan Lake International Innovation and Entrepreneurship Community