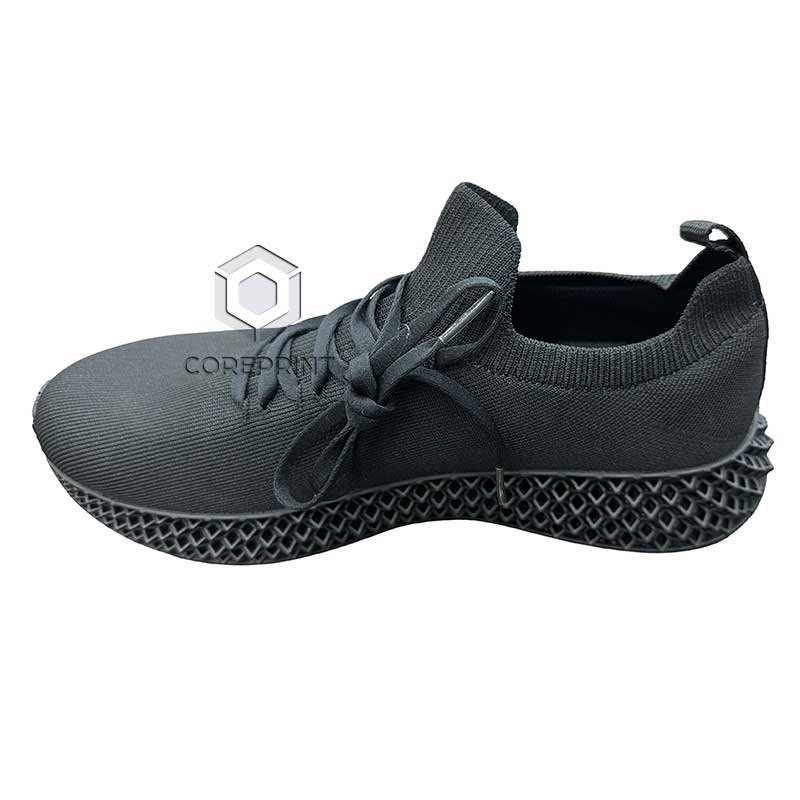

TPU

Thermoplastic Polyurethane (TPU) is a flexible material commonly used in 3D printing, suitable for FDM technology. It typically requires a printing temperature of 200–240℃ and a heated bed (50–80℃) to enhance adhesion, with a low shrinkage rate (0.3%–0.8%). However, fan speed must be controlled during printing to prevent excessive cooling and interlayer delamination. Its printed parts feature high elasticity (Shore hardness A80–D40), excellent elongation at break (300%–800%), abrasion resistance (wear volume ≤50mm³), and tensile strength of 15–40MPa, making them suitable for manufacturing flexible functional components such as seals, wearable devices, and shock-absorbing parts. TPU has relatively high hygroscopicity (water absorption rate 0.4%–0.7%), requiring drying before printing. Additionally, its high flowability tends to cause nozzle clogging, so large-diameter nozzles (≥0.4mm) and lower printing speeds (30–60mm/s) are needed to ensure forming accuracy.

18-TPU_Materials

| Tensile Strength/Modulus (Mpa) | Yield Strength/Modulus (Mpa) | Elongation (%) | Shore Hardness (D) | Heat Deflection Temperature (°C) |

| 18/61 | 6.2/86 | 276 | 88 | 169 (Melting Point) |

显示 1-12 个结果(共 34 个结果)